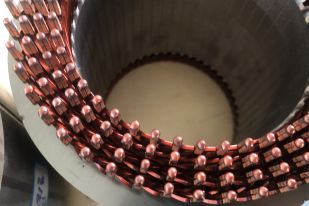

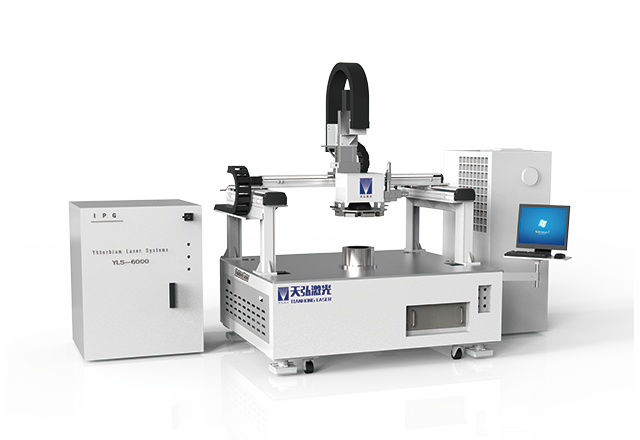

Flat wire motor hairpin welding system

Features:

» Visual positioning of the full field of view, editable without dragging.

» Using the visual galvanometer for high-speed welding, no matter when welding the flat copper wire of the single-layer or multi-layer HairPin motor, the efficiency is greatly improved compared with the original gas gourd welding process.

» The speed of a single solder spot is about 200ms, large-format visual positioning, and multiple spot soldering at one time.

» Customized and developed welding special software, which can write ID for each pin, and judge whether the splicing gap meets the welding standard, and give NG alarm to the non-compliant pin, give PLC control signal, and the laser does not emit light to prevent welding. The scrapping of the entire product.

» When the spacing, etc. meet the requirements, the welding trajectory will be automatically moved to the detected target coordinates.

» Use vision to locate each PIN to ensure the welding effect.

Contact us

Company address

No. 66, Tonghe Road, Weiting Town, Suzhou Industrial Park

Website

Douyin