Sculpture subcategory 1

- Categories:镭雕下属子分类

- Time of issue:2022-10-14 13:23:22

- Views:0

Laser Engraving

Laser engraving processing uses CNC technology as the basis, laser as the processing medium. Processing material in the laser irradiation instantaneous melting and vaporization of the physical denaturation can achieve the purpose of processing. Laser processing characteristics: non- contact with the surface of the material, not affected by mechanical movement, the surface will not be deformed, generally do not need to be fixed. Not affected by the elasticity and flexibility of the material, convenient for processing soft materials. High processing precision, fast speed, wide range of applications.

Light source

CO2

Fiber

UV

Laser engraving material

Metal material

Nonmetallic material

Brittle material

Engraving performance

Engraving speed

Engraving format

Spot size

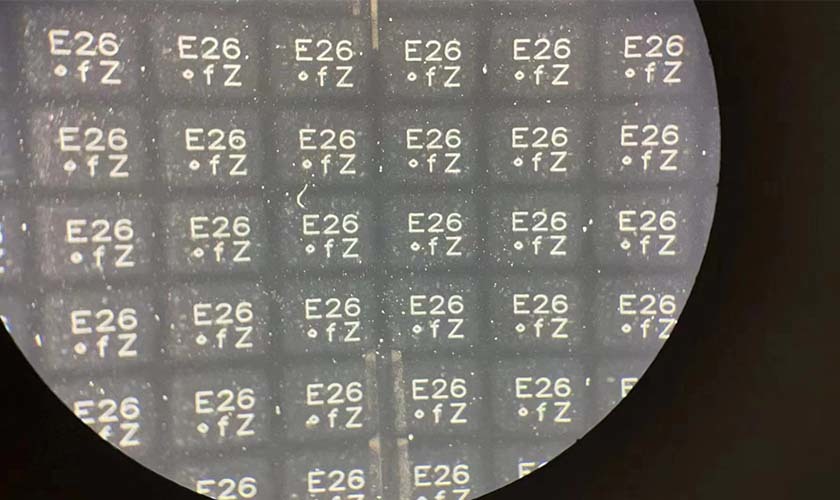

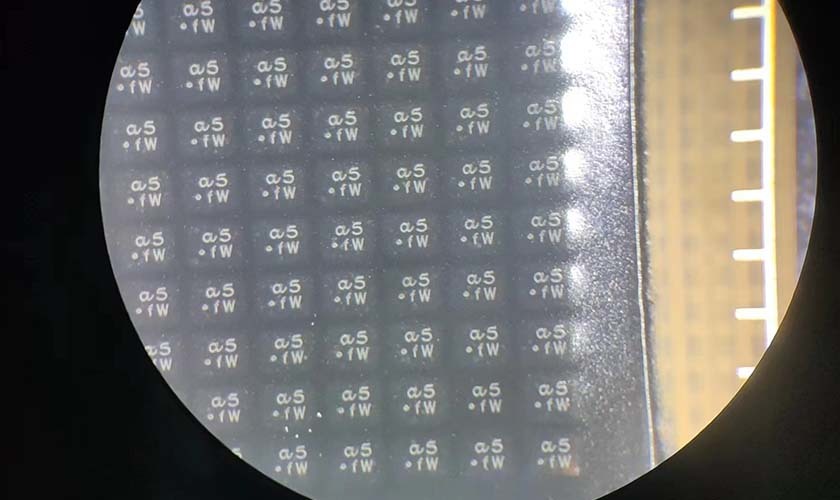

Typical Case-Semiconductor Industry

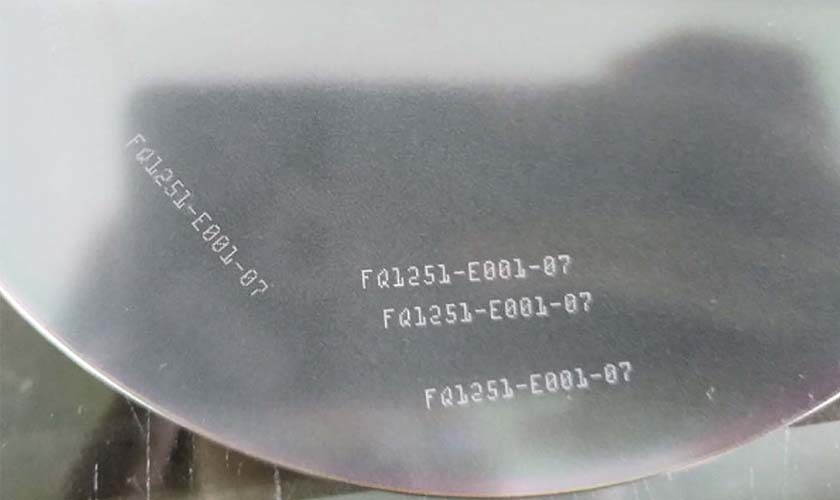

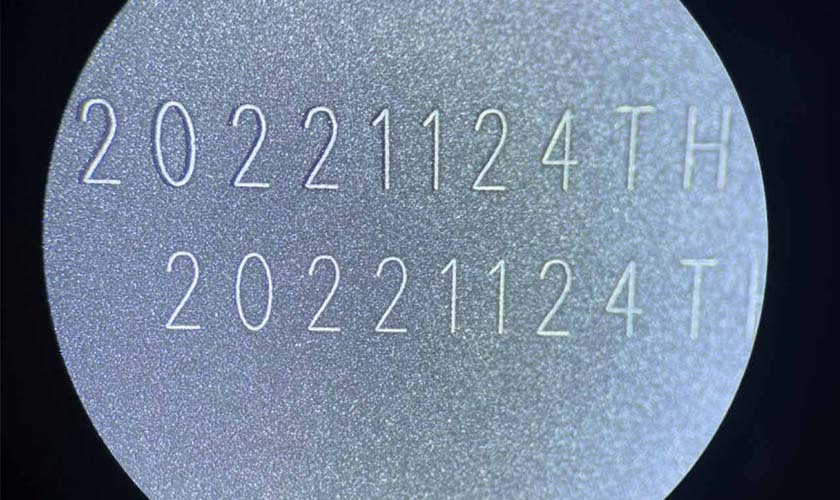

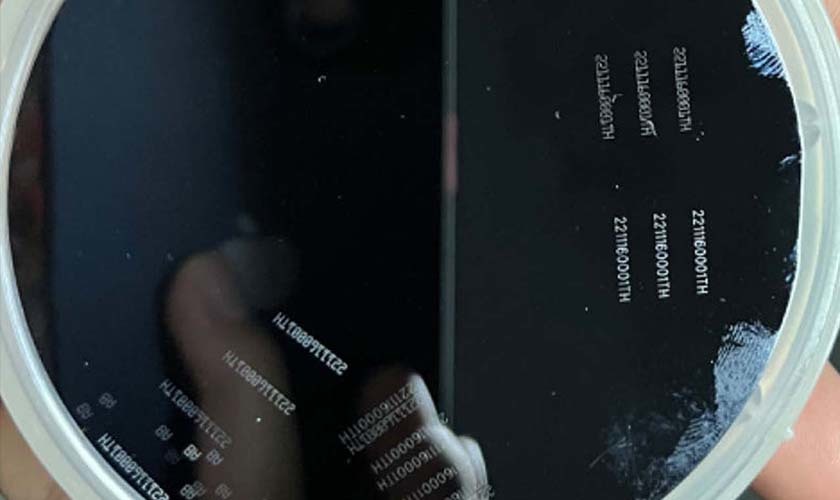

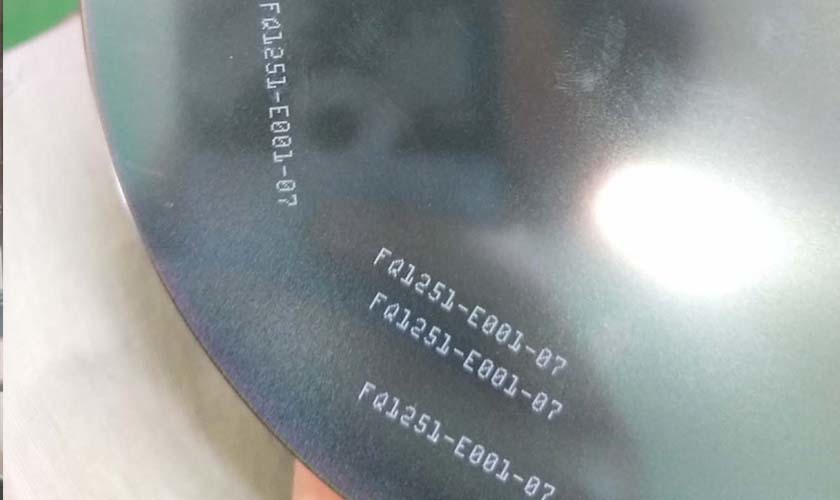

With the development of innovative applications such as automotive electronics and 5G, semiconductor chips are developing rapidly in China. Wafer is a key raw material in the production of semiconductor integrated circuits, because it is a special material between the conductor and insulator, thus becoming the main material of electronic components. Traditional ink marking machine belongs to the contact processing in the marking process, which will not only cause damage to the chip, but also lose color and fall off due to the limitations of the traditional marking technology. It is difficult to meet the modern wafer marking processing needs and is gradually eliminated. Tianhong laser marking process can be a good solution to these problems. Laser marking machine belongs to non-contact processing. Adopt high energy density of laser light on the workpiece for local irradiation, so that the surface material vaporization or chemical reaction of color change, thus leaving a lasting mark. The advantage is that it does not need curing treatment. Also with short process and small laser beam spot.Can play fine, hierarchical graphics and do lasting marking. It will not fall off because of time changes in color, difficult to modify. Can effectively protect the brand and play a good role in traceability.

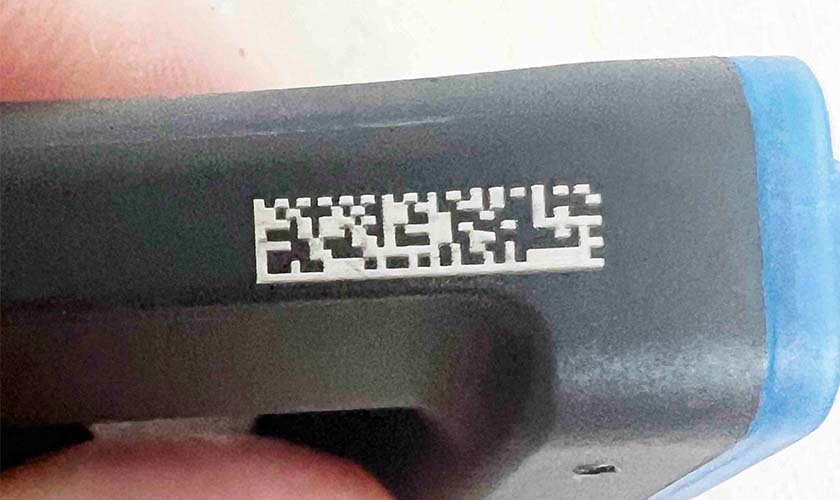

Typical Case-3C Industry

With the development of science and technology, 3C products, as popular consumer electronic products, are becoming more and more diversified in terms of shape and function.

Due to the overall appearance of 3C products is small, processing precision requirements are high, so 3C enterprises have to look to the field of laser processing. Tianhong laser marking machine processing heat-affected area is small, processing is fine, processing speed is fast. It can make processes that are not possible with conventional methods easy to realize, thus making it popular with 3C companies.

Typical Case-Automobile Industry

With the development of the automotive industry, laser marking machines are increasingly used in automobiles. Such as:Frames, chassis, water pumps, exhausts, connecting rods, driveshafts, engine VINs, brake discs, transmissions, and more.Traditional automotive marking are screen printing, pneumatic marking, inkjet code scanning, galvanic corrosion marking and so on.Due to these marking methods have certain contamination properties, inaccurate marking effect, easy to lose color, easy to be painted and then change the product information and so on.Tianhong laser marking machine can not only be widely used in automobile manufacturing, but also can be applied to the 3C electronics industry, semiconductor industry, intelligent machinery and equipment, household industry, hardware industry, plastic products industry and so on.

Process Features

Fast Marking Speed

Effective combination with modern automation and computer system, so as to realize the purpose of rapid processing and improve the processing efficiency.

High flexibility in laser engraving

With a wide degree of freedom over the material, shape, size and processing environment of the processing object, it is particularly suitable for automated processing and special surface processing, and flexible processing methods.

High accuracy in laser engraving

Wide adaptability to materials allows for very fine marking on a wide range of surfaces with excellent durability.

Processed material wide range

A wide range of non-metallic and metallic materials can be processed, including brittle materials, high melting point materials, and high hardness materials.

Non-contact engraving

There is no machining force between the workpiece , which is characterized by non-contact, no cutting force, and low thermal influence, thus ensuring the original accuracy of the workpiece.

Permanence and anti-counterfeiting

It does not fade in relation to the environment and cannot be easily copied or altered.

Application Industry

Medical Industry

Electrical Industry

Semiconductor Industry

3C Industry

Aerospace

Hardware Industry

Automobile Industry

Mould Industry

Advantage

OFTWARE

MOTION CONTROL SYSTEM

OPTICAL SYSTEM

Sculpture样式表

Sculpture样式表

Contact us

Company address

No. 66, Tonghe Road, Weiting Town, Suzhou Industrial Park

Website

Douyin